BOXMATIC Short Run Box Makers

Watch Boxmatic Video

Production range

BOXMATIC 18 DCP – working width 1,8m + die cut + print

BOXMATIC 23 DCP – working width 2,3m + die cut + print

| Technical data | |

|---|---|

| max. sheet dimension [mm] | 1800 (2300) x 4000 and unlimited |

| min. sheet dimension [mm] | 300 x 600 |

| productivity [pcs/hour] | |

| – singleproduction | 200 – 600 |

| – multiproduction | up to 2000 |

| dimensions [m] | 5.5 x 4.0 x 1.9 |

| weight [kg] | 5500 |

| electrical supply | 3x400V, 50Hz, 15kW |

| air supply | 8 – 10 kPa, 290 l/min |

| cardboard thickness [mm] | 2.0 – 8.0 |

Boxmatic line

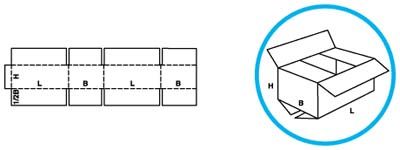

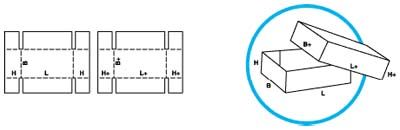

Universal machine of the Boxmatic range for production of Regular Slotted Containers (RSCs) with the option of supplementary die-cut (e.g. for handholes) and print (e.g. for RESY logo). The machine can be also used to produce grids or just cut and crease boar d. The production of basic RSC (namely FEFCO 02xx, FEFCO 03xx etc.) is possible using single or doublewall corrugated cardboard. Under certain circumstances, it is also possible to process triwall.

- slotting and crosswise creasing

- lengthwise creasing

- crosswise cutting with the option to simultaneously cut out flaps

- lengthwise cutting

- supplementary die-cut

- supplementary small area print

Automatic loading unit

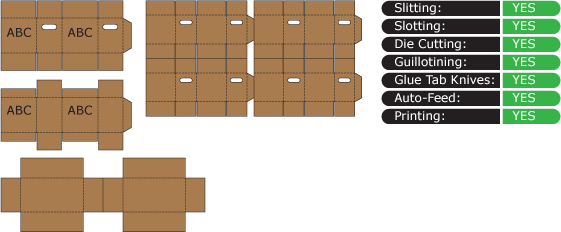

Supplementary die-cut

Depending on customer’s wish, the machine can sport supplementary equipment for multiproduction and/or up to three printing units.

Programming and entering parameters is simple and quick thanks to color touchscreen control panel. Only the neccessary parameters have to be entered, the machine will compute the rest. The positions of printing units, die-cut blocks, wheels, knives etc. can be set quite easily by hand according to the figures given by the machine.

Thanks to that, the machine is easy and fast to set up and therefore it’s best for short-runs of 5.000 – 10.000 boxes.

FEFCO styles produced by the machines:

- Version Boxmatic:

0200, 0201, 0202, 0203, 0205, 0208, 0209, 0214, 0230, 0231, 0300, 0301, 0306, 0310, 0312, 0313, 0320, 0331, 0404, 0405, 0409, 0411, 0412, 0413, 0452, 0453, 0454, 0455, 0501, 0502, 0503, 0504, 0505, 0507, 0509, 0510, 0621, 09-series

- Version Boxmatic DC:

version Boxmatic + 0204, 0206, 0228, 0229, 0302, 0325, 0400, 0401, 0402, 0403, 0406, 0410, 0441, 0456, 0458, 0511, 0512, 0601, 0602, 0605, 0606, 0607, 0608, 0610, 0615, 0616, 0620

FEFCO 0201

FEFCO 0300

FEFCO 0404

FEFCO 0411

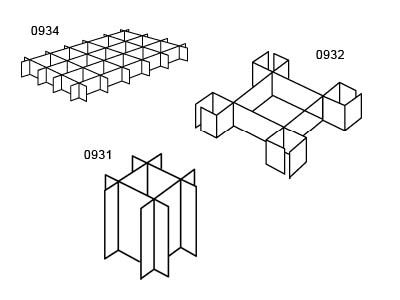

FEFCO 09