ETERNA ECUT1060 ELITE CLASS: ER

Automatic Autoplaten Die-Cutter

With Blanking and Stripping Capabilities

Introduction

The ETERNA 1060 ELITE ER die-cutter with waste stripping and full blank separating represent the very latest technology in make-ready, product quality and efficiency in an unrivaled package.

Blank separating makes substantial savings for carton makers, by delivering perfectly stacked blanks removing the need for time-consuming hand stripping.

Designed for quick, efficient make-readies and high net output, it also appeals to those carton makers who also wish to run a combination of blanked and non-blanked work using existing tooling.

The delivery can simply be converted to allow ‘full sheet delivery’ using a special frame in a matter of minutes. While a number of latest new technologies are adopted, many proven features are also integrated into the 1060 ER. Normally only be seen in the world-class products of our group these features are integrated at the same time to make it reliable and risk-free.

The compatibility of tooling from existing machinery is assured and fits perfectly using the standard quick-locking features of the cutting chase, waste-stripping and blanking unit frames. Suitable for BSI blanking tools that lower the cost of blanking for jobs that were previously seen as too costly to make.

VIDEOS

Introduction

Factory Test

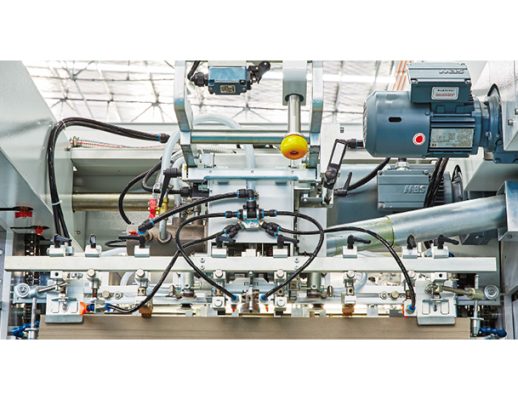

High Precision

- Short stroke movable platen, driven by eccentric worm gear and toggle mechanism allows large motion angle (265 degree)

- 3-cam index gripper bar drive system to ensure smooth intermittent movement

- Eccentric worm gear for balanced die-cutting pressure

- Stationary middle stripping frame

- Center-line system throughout the entire machine

High Efficiency

- High speed feeder with solenoid controlled suction

- Non-stop feeder and delivery

- Double sheet detector ; Accurate Side lay & Front lay

- Optimized micro-adjustment system of cutting plate

- One-button quick locking device for the upper tool integrated in the machine

- Reduce labor cost

- Produce the special job with high speed

Safety

- Gripper bar safety lock device

- Torque limit safety clutch

- Photo sensor safety barrier at pallet table

- CE standard safety system for safe operation

- Emergency stop at arm length

SPECIFICATIONS

| Maximum Sheet Size: | 1060 × 760 mm |

| Minimum Sheet Size: | 400 × 350 mm |

| Maximum Cutting Size: | 1060 × 745 mm |

| Inner Chase Size: | 1080 × 770 mm |

| Stock Range | Cardboard: 90~1000 g/m²; Corrugated board: Up to 4mm |

| Minimum Gripper Margin: | 9~17 mm |

| Cutting Rule Height: | 23.8 mm |

| Maximum Mechanical Speed: | 7500 cycles/hour |

| Maximum Cutting Pressure: | 260 tons |

| Total Power Required: | 27 kw |

| Electrical Power: | 415V, 50HZ, 3-phase |

| Air Pump Displacement: | 0.36 m³/min |

| Net Weight of Machine: | 25T |

| Machine Dimensions: | 9249 × 6036 × 2640 mm |