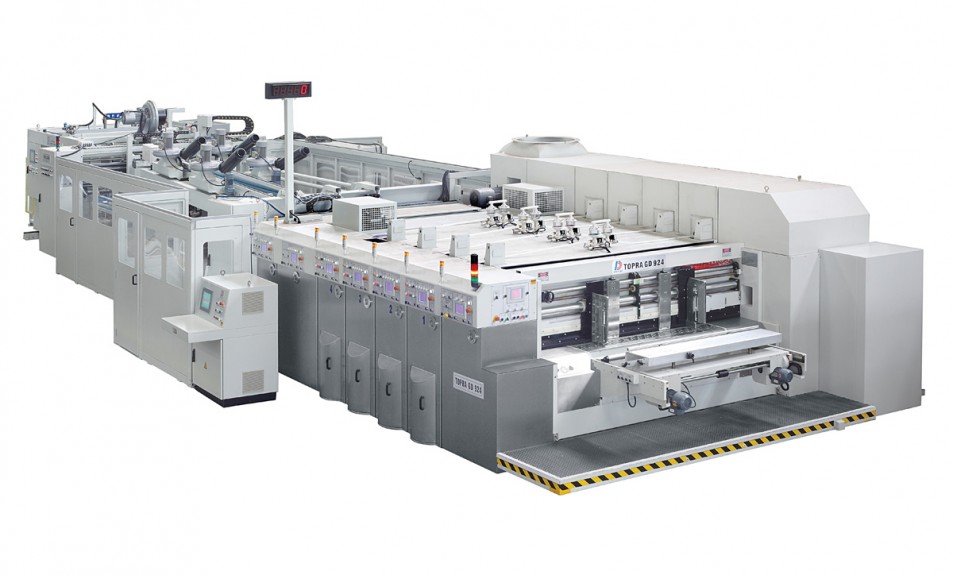

TOPRA GD Flexo Folder Gluer (FFG) Introduction:

The TOPRA GD Flexo Folder Gluer (Casemaker), is designed from the ground up to be a work horse in the production of RSC’s. It’s key design features include a state of the art folding section, fully servo counter ejector, chambered print units, vacuum transfer & a Sun lead edge feeder.

You can read more about each area of the machine by following the links on the left of this page.

Some of the key features of this machine include:

Machine Construction

The TOPRA GD is a “Gear Drive” top printing and mobile architecture machine. The machine can be configured with up to six print units, dwell unit, slotting unit, rotary die-cutting unit, folding section & counter ejector.

The feeder is a Sun lead edge feeder and the feeder unit has a sheet cleaner and vacuum box for stable feeding of the sheet into the first print unit.

Transfer of the sheet through the machine is vacuum via a series of ceramic coated wheels.

Print Quality

The TOPRA GD has a great capacity for high quality printing. The anilox roll is ceramic and the engravings can be customised to your specification. Supply of the ink is done with either chambered or single doctor blade metering, with rubber rolls available as an option. Supply of the ink is via a dual pump system with a Peristaltic supply pump and pneumatic diaphragm return. Registration of the print is excellent with a tolerance of ± 0.5mm first to last print unit.

Slotting & Creasing

One of the exciting parts of the TOPRA GD is the level of customisation available in the slotting section. We can supply you with a standard unit or a dual creasing shaft unit for those difficult to crease paper grades. One of the newest innovations is the servo driven dual slotting shaft system. With this system swapping knives in and out of the machine between jobs becomes a thing of the past as one shaft is tasked to the leading edge and the other to the back edge. Another unique feature of the servo dual shaft slotting section is that the full extended skip feed length of the machine is addressable.

Folding & Gluing

This is another area where upgrading to the TOPRA GD offers real benefits. The folding section on the machine features servo driven independent belts in the final section for combating fish tailing. We have also employed a series of lugs that the crease is formed against, the profile of these lugs changes over the length of the machine and as a result we get very square boxes.

- Dedicated computer controls are provided and orders can be stored and recalled by the local PLC controls.The machine also allows for quick and easy setup of orders and an increased level of convenience of operation.

- Remote diagnostics can be performed by means of a remote ethernet connection.This makes maintenance and monitoring more effcient and reduces the post-installation support costs.

- All drive shafts are made of high-quality steel,and are surface ground and chrome plated for longevity.

- All driving gears are hardened and ground.

- All units of the machine can be separated automatically or manually and an audible alarm sounds during the opening and closing for safe operation.

- Every unit is also equipped with an emergency stop switch for increased safety.The machine operator,working inside each unit can stop the unit from moving at any time.

- The machine is also equipped with an automatic lubrication system that keeps the lubricant levels in all of the units uniform at all times

Videos

Main Specifications

|

Item

|

TOPRA GD 920

|

TOPRA GD 924

|

TOPRA GD 1224

|

TOPRA GD 1228

|

|

|

Max.machine speed (pcs/min)

|

280

|

280

|

250

|

250

|

|

|

Max.feeding size (mm)

|

900 × 2000

|

900 × 2400

|

1200 × 2400

|

1200 × 2800

|

|

|

Min.feeding size (mm)

|

300 × 750

|

300 × 750

|

350 × 750

|

350 × 750

|

|

|

Skip feeding (mm)

|

1200 × 2000

|

1200 × 2400

|

1500 × 2400

|

1500 × 2800

|

|

|

Max printing area (mm)

|

900 × 1960

|

900 × 2360

|

1200 × 2360

|

1200 × 2760

|

|

|

Printing plate thickness (mm)

|

7.2

|

7.2

|

7.2

|

7.2

|

|

|

Max.panel glue tab side (mm)

|

Max.panel opposite glue tab side (mm)

|

912.5

747.5 |

1100

947.5 |

1100

947.5 |

1100

1145 |

|

Min.panel sizes normal knife (mm)

|

Min.panel sizes reverse knife

|

230×130×230×130

230×120×230×120 |

230×130×230×130

230×120×230×120 |

230×130×230×130

230×120×230×120 |

230×130×230×130

230×120×230×120 |

|

Max.slotting depth (mm)

|

260

|

260

|

300

|

300

|

|

|

Min. Glue Flap (mm)

|

<45

|

<45

|

<45

|

<45

|

|

Counter Ejector Specifications

| Counting (pcs/Bundle) | B Flute | 10, 15, 20, 25, 30 |

| C Flute | 10, 15, 20, 25, 30 | |

| A Flute | 10, 15, 20, | |

| AB Flute | 5, 10 | |

| Max. machine speed | 5 pcs/bundle | 75 (pcs/min) |

| 10 pcs/bundle | 150 (pcs/min) | |

| 15 pcs/bundle | 225 (pcs/min) | |

| 20 pcs/bundle | 300 (pcs/min) | |

| >25 pcs/bundle | 350 (pcs/min) | |

| Height of bundle ejection (mm) | 700 | |