Function of the TOPRA GD Folder & Counter Ejector Unit

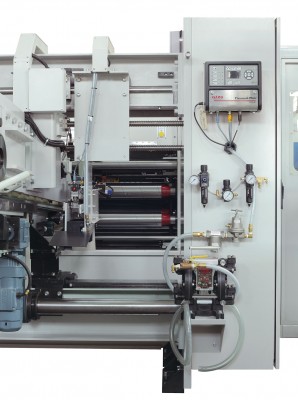

The TOPRA GD Folder & Counter Ejector Unit has been designed to face the unique challenges of today’s box maker. Along with the push for increased run speeds is the proliferation of die-cutting in the manufacture of RSC’s and a move towards tighter tolerances on fish tailing. The TOPRA’s unique combination of features provide answers to all these production dilemmas. The top loading counter ejector is servo driven and provides perfect stacking of finished RSC’s in predefined bundle counts and well handles die-cut cartons. Servo controlled folding belts provide adjustment for carton skew and lugs assist the forming of the box and prevent fish-tailing.

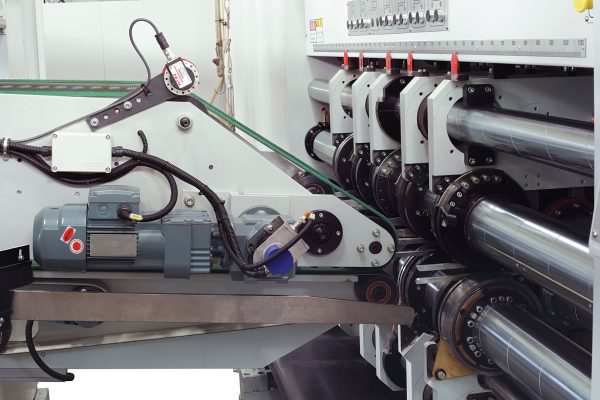

- Vacuum transfer upper belts, the gap can be adjusted according to the thickness of the paperboard

- Lower transfer belts fold to 90 degrees in the first transfer section for precise sheet control

- The final transfer belts are servo driven and the speed can be adjusted independently to reduce fish-tailing

- Rotating forming lugs ensure a square carton.

- Valco or ERO High Pressure non-contact glue systems can be supplied as standard.

- Counter ejector is fully servo driven for smooth operation at all sizes and machine speeds.