Cut Off Knife – Master

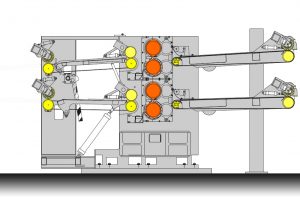

The Master cut-off knife is comprised of three main sections – the infeed delivery section, the cutting section, and the outfeed delivery section.The infeed delivery consists of a supporting plate to hold the board with an independently driven pull-roll section. The delivery infeed section can be rotated back and away from the cutting section via pneumatic cylinders. This creates a space to allow convenient and immediate access to the knife bars and facilitates blade tuning and general maintenance of the machine. The infeed section can be upgraded to include a secondary no crush pull roll section to provide additional control of the incoming web for higher speed operations.

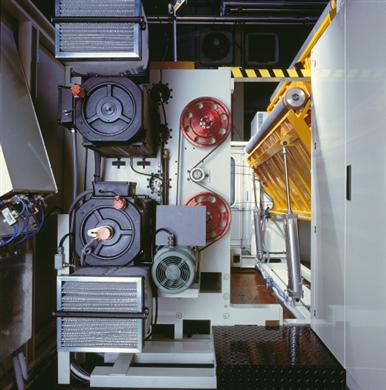

The cutting section consists of a pair of steel knife bars on which the single-piece blades are mounted. Single piece helical knife blades are utilised to soften the impact of the cut action on the knife bars. In this way very low inertia shafts can be used. The position of the upper blade is fully adjustable via the regulating screws housed in the knife support, an integral part of the knife bar, to hold the blade in position for optimum tune. A specially designed self lapping procedure facilitates tuning for the operator and ensures the blades are kept fine-tuned and sharp at all times. Rotation of the shafts is guaranteed by meshed gears (one for each side) fitted at the head of every knife bar for positive drive between them.

The intelligent design of the Master cut off knife allows for short sheets to be run at the industries highest line speeds. The outfeed delivery section consists of an independently driven no crush exit roll. The outfeed section can also be upgraded to an independently driven anti-skew belt section for the highest control of sheets exiting the knife regardless of speed.

In order to meet different production requirements the Master is available in various performance levels, corresponding to the number of drive control units. All drive motors are brushless AC motors and cut length precision is guaranteed via a Vector Drive Control with a power recovery system, greatly reducing power consumption.

The Master cut-off knife is run by a high performance control system featuring: Order visualization, Machine Status, production Data, Fault Diagnosis, and Operator override facilities. The system also allows the Master to communicate with other dry-end machinery and scheduling systems, as well as enabling remote access via modem or network connection for additional Fosber diagnostic and support services.

Operator safety on the Master Cut-off knife by use of extensive guarding and lockout devices will satisfy the most stringent of company or government standards.