Double Facer – Express

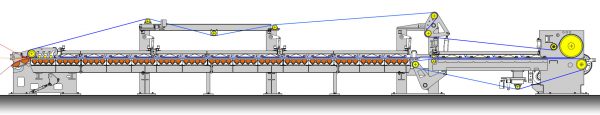

Utilising the most up-to-date technology available today the Express double facer is capable of running the full range of board grades up to 350 mpm, up to a maximum paper width of 2800 mm. Gradual and efficient heat transfer is precisely managed and controlled to achieve and complete an optimum bond whilst maintaining an equal moisture balance according to the running speed and particular board grade being produced.The Express double facer consists of a heating section, subdivided into two or three independent stations with the option of an additional independent “zero section” right at machine infeed as well as an AC driven traction section. At the inlet of the machine, the Express is fitted with a standard curved hot plate to preheat the bottom liner or with a 500mm diameter preheater drum with variable motorised wrap arm control.

The main heating section is composed of a series extra large heavy-duty spheroid cast iron hotplates each 750 mm long in machine direction to prevent heat deformation. Thanks to its fully modular design the overall length of the heating section is fully flexible from a 9 to a 20 hotplate machine configuration depending on each customer’s individual production needs.

The cast iron hotplates are manufactured using a single casting and provide much superior thermal stability when compared to steel and result in a very durable, uniform, and low-frictional surface contact with the board over a much longer life. The hotplates are formed with an internal serpentine loop specifically designed to provide a continuous, high volume fluid steam flow inside the chest. This process ensures a very efficient heat transfer whilst removing condensate, which is then fully recovered via the on-board steam system design. Each independent steam section can run from 15 bar down to 0.5 bar. The result is a perfect and uniform heat distribution to the surface of the board.

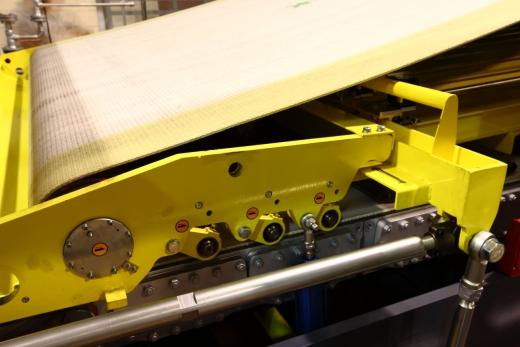

To exert a constant and even dispersion of pressure on the web the Express utilises a series of specially designed full-width yet semi-rigid shoes attached via a spring steel design to an upper moveable I beam support structure. In this way pressure is perfectly equalised at both ends of the shoes right across the full width of the web thus preventing spiking. Downward force of the shoes is exerted by variable controlled hydraulic cylinders fitted at the ends of each separate shoe section.

The outer I beam shoe support bars can be individually raised via pneumatic actuators and at the same time the whole shoe support frame structure can move laterally with respect to the centre line so pressure can be lifted off the belt right at the point of the board edge. This prevents edge crush and prolongs belt life.

The machine program allows the shoe pressures to be set either constantly or gradually (from high to low or vice versa) in board direction according to line speed and type of quality being run. Thanks to independent heating and pressure sections with separate controls, maximum flexibility is provided in terms of the automatic setting of shoe and steam pressures according to the board quality being run. The on-board touch screen control allows operators to control and set all double facer functions and processes within its database as recipes for the various qualities run. It also displays diagnostics, machine status and maintenance operations.

Similar to the heating section the traction section consist of a series of unheated plates below the web and a set of spring loaded full width pressure shoes from above to exert an adjustable and uniform pressure on to the board over a large contact area to optimise board quality.

The head pulley section is fitted with a more energy efficient AC drive system sized and configured to individual performance requirements as either a single or a double AC motor arrangement. Both upper and lower belts are fitted with an automatic tracking and alignment system as well as a heavy duty self-tensioning device to eliminate slack and further prolong belt life as well as enhance board quality.