Dong Fang Opens New Factory

November 19th, 2014 saw the official opening of Dong Fang’s brand new manufacturing premises located in Foshan China.

The idea behind the move was to increase the production capacity for the flexo business which due to the floor space, was constrained to an already impressive 16 machines per month. The new factory seeks to more than double this capacity as well as providing space for the production of Fosber Corrugators for the Asian Market and materials handling equipment through the Joint Venture that was just announced with EDF Europe. Dong Fang is already the worlds 4th largest manufacturer of Corrugated machinery and is seeking to build on this position.

The new complex is divided up into sections: The office complex, Residential apartments & facilities, CNC Parts manufacturing area & Assembly shop

The CNC Parts Workshop

As part of the new factory build Dong Fang has invested 17 million US dollars in new CNC machining equipment.

The Strategy of Dong Fang is to keep the focus on quality by housing all aspects of the machinery build process entirely in-house.

The area covered by the parts processing workshop is 10,000 square metres.

CNC Mills

Through the use of 6 Brand new CNC gantry mills, Dong Fang is able to produce all of the side frames and other such components.

CNC Lathes

In addition to the CNC milling machines, Dong Fang has purchased multiple CNC lathes and boring machines for the production of shafts and cylinders

CNC Machining Centres

The CNC parts shop also features an area for the production of smaller CNC components such as vacuum transfer boxes and glue tab knife holders.

The Assembly Shop

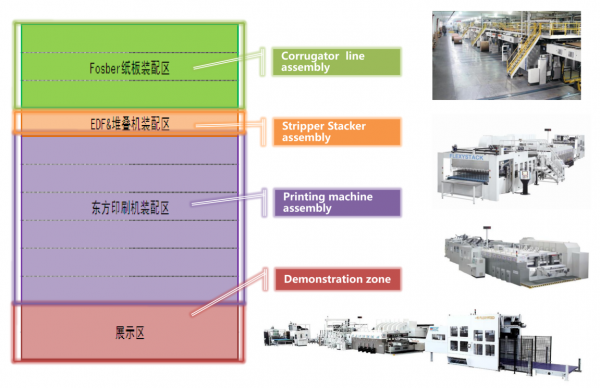

Bigger than most air craft hangers, the Assembly shop has been designed specifically for the manufacture of corrugated equipment. It has been divided into sections as shown in the plans below:

Cell based manufacturing sees a team responsible for each component of the machine such as a TOPRA GD Print Unit team. Each unit is assembled on calibrated machine bases and then craned onto the transfer cart and moved to the assembly area.

The assembly area has a range of rails installed into the ground for machines of different widths: 2000mm, 2400mm, 2800mm, 3200mm, 3600mm etc.

Each machine is assembled on the rails and tested. Customers from Australia & New Zealand normally send a representative with us to sign the machine off prior to shipment and are able to view the machine operating at typical production run speeds.

Offices

These modern offices house seven floors of office space and meeting rooms. During the open house we held a technical conference in one of the rooms that can comfortably hold 200 people.

Apartments and Employee Facilities

Dong Fang workers have the option of staying onsite in fully furnished modern hotel styled apartments. There are three apartment blocks, each with eleven floors, for a total of 600 apartments accommodating over 1,000 people. Facilities also include two cafeterias, gymnasium, library, recreation room and basketball courts.

Dong Fang workers have the option of staying onsite in fully furnished modern hotel styled apartments. There are three apartment blocks, each with eleven floors, for a total of 600 apartments accommodating over 1,000 people. Facilities also include two cafeterias, gymnasium, library, recreation room and basketball courts.